Modern production of electricity and heat from biomass

ENERGOBLOK ORC BPOWER

|

For more information, please

contact us

Mgr. Pavel Žwak

Email: pavel.zwak@bpower.cz

Phone.: +420 725 902 003

|

ORC stands for Organic Rankine Cycle. This is a classic condensation cycle. However, instead of water vapor an organic substance is used as the medium. Thus it is the transformation of thermal energy into electricity.

The reason why other medium is used rather than water is simple. An ORC device works with such input

temperatures and such temperature levels which a standard steam cycle cannot cope with effectively.

An ORC unit uses flue gases from a hot-biomass boiler as an input medium. The flue gases in the heat exchanger (evaporator) heat the operating medium of an ORC system and it leads to a large expansion on the turbine blades. This way, the whole system begins to produce electricity. Excess heat from the cooling system is then used as useful heat for heating buildings, dryers, etc. The energy block uses the system ORC Triogen.

An ORC unit uses flue gases from a hot-biomass boiler as an input medium. The flue gases in the heat exchanger (evaporator) heat the operating medium of an ORC system and it leads to a large expansion on the turbine blades. This way, the whole system begins to produce electricity. Excess heat from the cooling system is then used as useful heat for heating buildings, dryers, etc. The energy block uses the system ORC Triogen.

Who is the Energoblock intended for?

Anybody who consumes heat - hot water:

- Boiler and heating plants, including the connection to the central heating supply

- Woodworking factories (drying ovens for wood etc.)

Why produce electricity and heat from biomass using technology of Energoblock

BPOWER?

Operating the technology the producer of electricity and heat from biomass obtains the possibility of partial or full independence from

prices of electrical and thermal energy. Furthermore, the operator of such technology is provided with::

- Significant economic benefits

- Variability of possible technical solutions

- Easy implementation into existing systems of electricity and heat

- Possibility to obtain support for electricity energy and heat from biomass in the form of CHP

- Easy installation with little use of space

- Minimum operation and maintenance costs

Feedstock into boiler is wood chips, wood waste material from production or sawdust with humidity up to 55%.

The temperature of the flue gas supplied to the ORC is about 520°C.

Combined production of electricity and heat - operation philosophy.

Solution concept of combined production of electricity and heat consists in the online coverage of consuming electricity and heat in time. These two commodities are not primarily separated from one another but the necessity of the best operational efficiency is taken into account.

The technology does not choose the policy to maximize sales of electrical power into distribution network, but on the contrary, to consume the biggest share of electric power on spot. This leads to a sharp reduction in costs for the purchase of electricity and considerable savings. Then all operational support, such as CHP, etc. are a pleasant bonus for the

operator, but not a vital component of revenues.

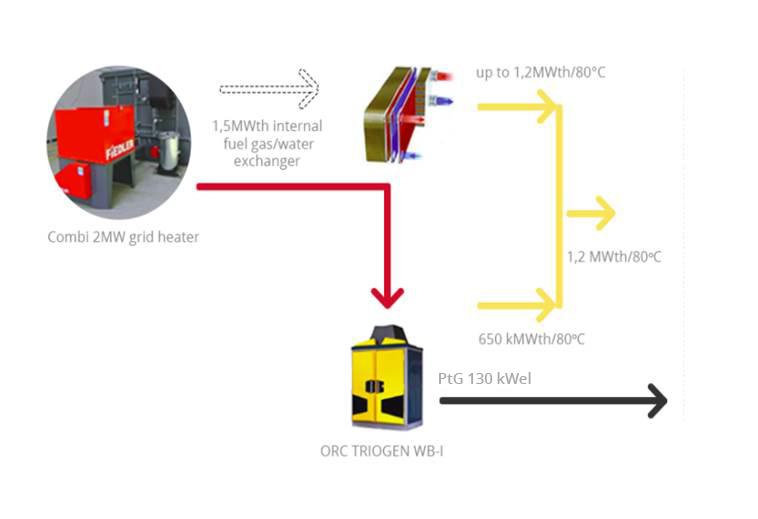

CASE STUDY - ENERGOBLOCK 1,2 MWth, 130 kWel

Energoblock is a hot-air boiler with a thermal 2MWth grid power, ORC module, and a bypass flue gas/water heat exchanger. The reasons to choose this concept are the following::

- full control band of heating supply in the summer and winter season.

- permanent heat supply in case of a service shutdown of ORC.

- the boiler is connected to the heat management, where there are a flue gas/water exchanger and an ORC system for generating electricity and hot water.

- regulation and preparation of hot water respond to the current heating system needs and hot water consumption.

There is no need to install any additional backup systems or hot water tanks.

Such plant collects:

- Green bonus for generating electricity

from biomass according to the fuel category (O1, O2, O3)

- CHP biomass component

- Saving own energy - covering own consumption

- Green bonus for biomass heat

How does an investor find out whether the technology is useful for them?

- I own a technology that consumes heat (drying oven for wood, etc.), or a central heating system (DH), with all-year-round and heat delivery?

- Do I need in average at least 600Kw heat/hour? (You can check the label and boiler annual operation, or the drying oven labels, etc.)

- Do I have space for placing ORC Energoblock sized 20 x 20 m?

- Is there also a distribution system located near the place?

Proportion of the supply:

- Delivery of the first technology and construction is complete – turnkey.

- We will help with administrative acts associated with the project (permits, connection to AC power energy, building permits, applications

for subsidies…).

- We cooperate with companies dealing with preparation for applying investment subsidies.

- We guarantee subsequent professional maintenance and 24/7 availability of our technicians.

What other questions must also be considered and what are the possible answers?

- I have biomass but I'm not sure that it is suitable for this technology, I do not know whether I have a sufficient amount.

Required fuel is waste wood biomass with a moisture content of 55%, sawdust, wood chips, etc. The annual consumption of one block ORC is up to 3 000 tones of woodmass with a moisture content of about 50%.

- I don´t know my heat consumption exactly.

If no records of annual heat consumption are kept, two things are sufficient at the start - the label performance of an existing power boiler, if it is installed and an annual fuel consumption, i.e. for example gas consumption, etc.

- I have my own electricity consumption. Can I use this source for covering this consumption?

YES. This is the ideal situation. The greater the percentage of covering their own electricity consumption from production in Energblock the better for the whole economics of the project. In the case, one unit produces approximately 130kW electricity hourly electricity, which is available for own consumption project.

WE WILL BE HAPPY TO PROVIDE ALSO YOU WITH THE SPECIFIC SOLUTION!

|

For more information, please

contact us

Mgr. Pavel Žwak

Email: pavel.zwak@bpower.cz

Phone.: +420 725 902 003

|