Advantages of ORC:

- high annual uptime

- high efficiency relative to the inlet temperature

- fully automatic operation

- easy integration into existing equipment

- suitable for modular installation

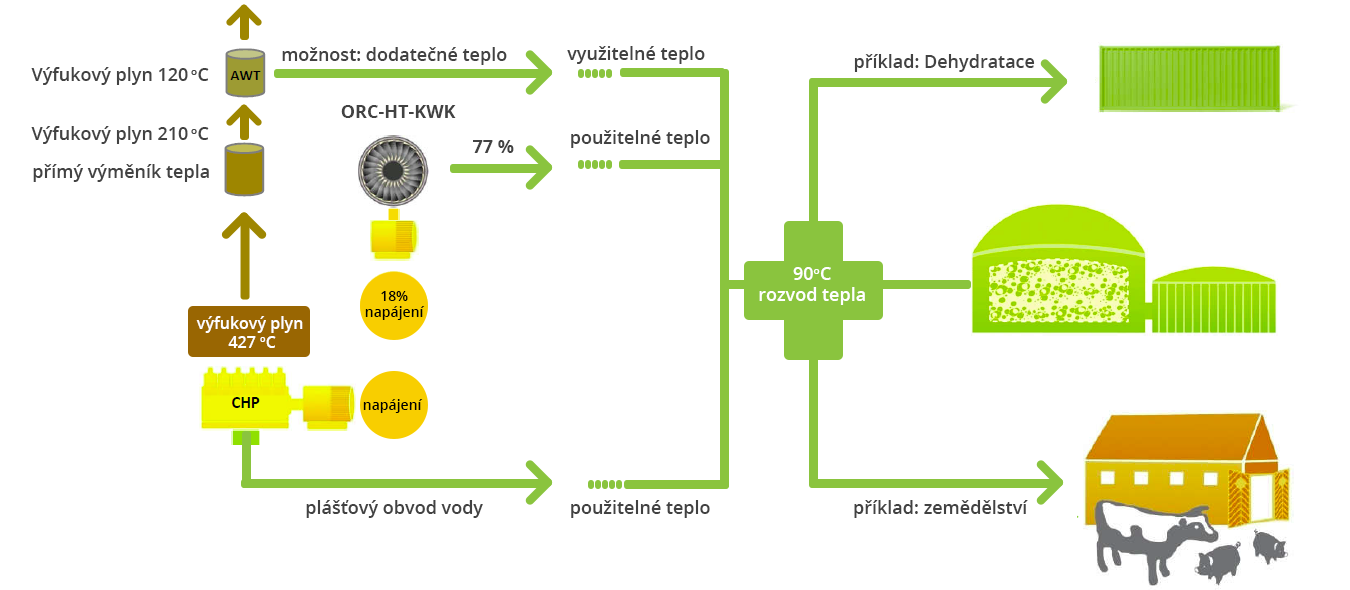

ORC uses only flue gases of the cogeneration unit engine. The cogeneration unit engine produces approx. 50% of the heat production in flue gases that can be used for the production of electric energy by means of the direct connection to the flue gas ORC. Thus the ORC behaves as an ordinary flue gas heat exchanger with safe meeting of the condition of the maximal anti-pressure of flue gases from the engine.

ORC uses only flue gases of the cogeneration unit engine. The cogeneration unit engine produces approx. 50% of the heat production in flue gases that can be used for the production of electric energy by means of the direct connection to the flue gas ORC. Thus the ORC behaves as an ordinary flue gas heat exchanger with safe meeting of the condition of the maximal anti-pressure of flue gases from the engine.

The secondary refrigeration circuit of the engine with hot water continues to be further preserved for the operator for further use, e.g. for heating of buildings, drying rooms, etc.

The output of cooling water from ORC has parameters from 55 °C up to 90 °C. Thus it is easy to achieve the operation of ORC in the regime of combined production of electric energy and heat – in the case of usability of heat from ORC or in the case of the same thermal potential of water from ORC and engine to interconnect both refrigeration circuits of both equipment into one circuit.

The flue gas ORC system makes sense on engines with an output of approx. 800 kW with a thermal output of 400 kW and above (or more engines with this total output).

Below the table of outputs for flue gas ORC´s in our offer:

| Thermal output in flue gases at temperature of 450 °C | Input electric output ORC (PtG - power to grid) |

| 400 kW | 70 kW |

| 730 kW | 120 kWel |

| 900 kW | 160 kWel |

| 1500 kW | 250 kW |

Fuel gases from the ORC system further exit via a chimney of a temperature of approx. 180 °C – 210 °C. This is also the temperature to which the efficiency of the whole system is additionally calculated that is approx. 18 - 22%. Thanks to characteristics and temperature parameters of the flue gas ORCs, the ambient temperature has a de facto negligible impact on the ORC system efficiency.

|

For more information, please |

WE OFFER THESE PRODUCTS

The main component of the ORC system is a high speed turbine which conver ts low-potential heat into electrical energy based on organic Rankine cycle.

Advantages of ORC:

Use of technologies:

ORC e-box POWER

ORC e-box Vario

.jpg)

→ ORC e-box POWER operates with flue gaseswithin the range 350 - 520 °C. Thermal power at the input to the ORC e-box POWER is 450 -990 kW while the electrical output power is 50 - 180 kWe, depending on the input heat fed into the ORC system.

.

An example of installation is a combination of the ORC system with a CHP unit. A great advantage is the ORC can be connected directly to the chimney flue gas pipe of the process. This eliminates the need to use a flue gas heat exchanger. Flue gases are passed directly to the ORC heat exchanger. The internal medium is not water, but an organic substance. It is heated to about 320 °C and when entering the turbine blades of the ORC it moves the turbine to speeds up to 28,000 rpm.

The connected asynchronous generator begins to generate electric power. Through the use of high temperatures directly from the flue gas, ORC e-box POWER achieves an efficiency of around 20%! This value puts ORC e-box POWER among the leaders in this technology. In the cooling circuit, the heat power is equal to 80% of the input heat power with the temperature gradient of about 55 °C - 35 °C. These are not random parameters as they provide the client with the possibility of using this potent i a l to heat the d i g e s t e r s , swimming pools, sludge pits, etc. The recovered flue gas coming out of the ORC flue gas pipe has a temperature of about 180°C.

→ The main reason why the ORC e-box VARIO system was launched onto the market was a high demand amongst potential clients for the use of heat to generate not only electrical energy, but also to use hot water for heating..

→ Variability of the ORC e-box VARIO operation enables the user to evaluate when the supply of heat into the heating system is a priority, or when it is more practical to maximize the production of electricity.

ORC e-box VARIO is technically identical to the e-box type, but it offers an additional feature of controlling the temperature of ORC cooling water so as to achieve different temperature levels. The settings can be changed online, depending on the operating conditions.

The ORC e-box VARIO system can be used with biogas plants (apart from other applications) which already have a supply of heat in place or which are planning it. By deploying the ORC e-box VARIO system, it is possible to streamline the entire operation and in the winter months to control the supply of heat ver sus electr icity production from ORC.

Graph of electricity production depending on the temperature of the refrigeration circuit:

ORC WB-1 characteristics and specifications:

|

Pro více informací nás |

illustrative picture of connecting the ORC Triogen ebox to a biomass heat source